Confused about the meaning of dust, combustible dust, particulate matter, PM2.5, PM10, coarse particulates, fine particulates, inhalable particulates, respirable particulates, nanoparticles, smoke, black smoke, black carbon, fibers, fumes, aerosols and mists? Concerned about how these may affect health and safety of your workers? Uncertain about your legal responsibilities and how to manage these hazards at your site?

Relax. You are not alone. This is a confusing topic and I’ve spent some time pulling together pertinent information for you. All you need to do is invest some time reading this blog post. You will then know what you need to know!

In the following sections of this post, I (1) provide a definition of these key contaminants, (2) list typical sources that lead to elevated levels in the workplaces, (3) discuss regulatory issues, (4) describe health concerns, and (5) offer suggestions to protect your workers from these hazards. I’ll conclude the post (in Part 2) with a discussion of what you can do to identify and evaluate whether you have a serious problem at your site.

There is a lot of information to cover, so, I have broken this down into two posts.

Part 1: Dust and Particulate Matter

Part 2: Smoke, Fumes, Mist and Aerosols

Feel free to skip to the section(s) that are of most interest to you and save the others for later review.

Dust

Definition: There are many different definitions for dust, some simple and some relatively complex. For our purpose, let’s use the one suggested by ISO 4225: 1994: “small solid particles, conventionally taken as those particles below 75 µm in diameter, which settle out under their own weight but which may remain suspended for some time“. To put the size of the dust particles in perspective, a typical strand of human hair is 100 µm in diameter, so we are talking about particles finer than the width of a human hair.

Sources: WHO provides a very good overview of issues associated with dust and how dust is generated, including both natural processes and workplace processes such as:

- mining, quarrying, tunnelling, stone masonry, construction, and any process which breaks or separates solid material

- foundries and other metallurgical processes, especially the cleaning of casting and breaking of moulds

- any process using abrasive blasting, such as removal of paint and rust, cleaning of buildings and small objects, and etching of glass

- manufacture of glass and ceramics

- handling of powdered chemicals in the chemical, pesticide, rubber manufacturing and pharmaceutical industries

- agricultural work involving exposure to soil, intensive animal husbandry, dry vegetable products, or agro-chemicals;

- food processing, especially where flour is used

- any process involving weighing, bagging, bag-emptying or dry transport of powdered or friable materials

Regulations: Dust on its own is not typically regulated in most developing countries, but certain constituents and size fractions within dust are often regulated (as discussed in the following sections). In the United States, OSHA PEL and NIOSH REL limits for dust are set at 15 mg/m3 and 10 mg/ m3, respectively.

Health: We all know that exposure to dust can cause red and itchy eyes, plugged noses, wheezing and coughing. But, as noted in an easy-to-read review article by Hazards Magazine, dust exposure can harm workers in a much more severe manner, including: chronic obstructive pulmonary disease (COPD), asthma, extrinsic allergic alveolitis (EAA), fibrosing alveolitis, pneumoconiosis, cancers and heart disease. These health-related issues for dust are a function of the sizes of the dust particles and constituents that are present.

Control: WHO and others suggest control measures for workplace dust, including:

- Elimination at the source – can involve three different items: the production process, the hazardous substance and the work practices.

- Containment – placing a physical barrier between the substance and people, for example putting a process inside a box;

- Ventilation – general ventilation is usually desirable to control the temperature and humidity of the environment, and a properly designed system can act as a back-up control of exposure to airborne substances by providing continual dilution of any accidental emissions.

- Work practices – work practices affecting exposure include:

- the manner in which containers are handled and lids are removed

- the care taken in transferring dusty materials

- work speed

- the way in which empty containers are handled

- Personal Measures – PPE to minimize exposure include:

- work clothing should not allow the collection of dust; problems such as gathering dust in pockets and shoes should be foreseen

- gloves and other skin protection are necessary if the dust may pose a hazard through skin absorption or ingestion, or can have a direct effect on the skin

- respirator selected and used as appropriate for the exposure conditions

Combustible Dust

Definition: A potential component of dust, OSHA defines combustible dust as “fine particles that present an explosion hazard when suspended in air under certain conditions”.

Sources: OSHA notes that a wide variety of materials that can be explosible in dust form exist in many industries. Examples of these materials include: food (e.g., candy, sugar, spice, starch, flour, feed), grain, tobacco, plastics, wood, paper, pulp, rubber, pesticides, pharmaceuticals, dyes, coal, metals (e.g., aluminum, chromium, iron, magnesium, and zinc). These materials are used in a wide range of industries and processes, such as agriculture, chemical manufacturing, pharmaceutical production, furniture, textiles, fossil fuel power generation, recycling operations, and metal working and processing which includes additive manufacturing and 3D printing.

Regulations: Combustible dust is typically not directly referenced and regulated in national HSE legislation. But, even if not specifically addressed it may be regulated indirectly, for instance with respect to general clauses related to providing a safe workplace for workers, ventilation requirements, explosion suppression systems, etc. So, it is incumbent upon the HSE officer to understand the potential for combustible dust at his/her facility, to be clear regarding the local regulations (if any), and to properly manage this issue.

Safety: This is a serious safety concern. For those interested, there are many informative videos on this issue, e.g., Combustible Dust: An Insidious Hazard describes this issue in detail and shows many examples of fires and explosions.

Control: Dust explosions require five elements: (1) fuel to burn, (2) oxygen, (3) ignition source (heat, spark, etc.), (4) dispersion of dust particles in the right concentration, and (5) confinement of the dust cloud. As such, preventative measures focus on eliminating one or more of these pathways using the following control measures:

- Eliminate:

- where possible, avoid horizontal surfaces (such as window ledges, beams, light fittings, etc. ) where dust can accumulate

- eliminate “hidden” areas where dust can accumulate unnoticed

- do not use brooms or compressed air hoses to clean surfaces; use vacuums approved for dust collection

- use a dust collection / dust extraction system that is designed to eliminate or control combustible dust (most models of fans typically stirs the dust, adding dust particles into the air and worsening the situation)

- install smooth ceilings and other surfaces (instead of a rough finish) to minimize dust accumulation and to make cleaning easier.

- Engineering:

- use an appropriate dust extraction and collection system

- direct venting away from areas where there may be employees

- use appropriate electrical and ventilation equipment

- keep all mechanical and electrical equipment in good repair

- keep static electricity under control

- check equipment that may wear (e.g., bearings) as they may generate heat and become an ignition source

- remove open flames, sparks, friction, heat sources, and other sources of ignition

- select and use intrinsically safe tools or machinery

- put covers around pipes and cables, or embed pipes and cables in the walls, where possible, to reduce surfaces where dust can accumulate

- Administration:

- develop and implement a combustible dust inspection and control program

- develop a hot work permit system for activities such as welding and cutting

- develop an ignition control program to eliminate or reduce sources of ignition

- educate all employees about combustible dusts, the hazards, and how they can help eliminate the risk of fire and explosions

- inspect for dust at regular intervals

- establish a housekeeping program that will remove dust regularly

- use proper equipment and techniques when cleaning dust

- regularly inspect machines, ducts, and ventilation systems for dust

Particulate Matter (PM)

Definition: IFC defines particulate matter (or more accurately airborne particulate matter) as dust, dirt, soot, smoke, and liquid droplets which when emitted into the air, is small enough to be suspended in the atmosphere. Airborne particulates may be a complex mixture of organic and inorganic substances. They can be characterized by their physical attributes, which influence their transport and deposition, and their chemical composition, which influences their effect on health.

Sources: IFC notes that some particulates come from natural sources such as evaporated sea spray, windborne pollen, dust, and volcanic or other geothermal eruptions. Particulates from natural sources tend to be coarse. Almost all fine particulates are generated as a result of combustion processes (i.e., smoke), including the burning of fossil fuels for steam generation, heating and household cooking, agricultural field burning, diesel-fueled engine combustion, and various industrial processes. Emissions from these anthropogenic sources tend to be in fine fractions. However, some industrial and other processes that produce large amounts of dust, such as cement manufacturing, mining, stone crushing, and flour milling, tend to generate particles larger than 1 µm and mostly larger than 2.5 µm. In cold and temperate parts of the world, domestic coal burning has been a major contributor to the particulate content of urban air. Traffic-related emissions may make a substantial contribution to the concentration of suspended particulates in areas close to traffic. The largest stationary sources of particulate emissions include fossil-fuel-based thermal power plants, metallurgical processes, and cement manufacturing.

Regulations: In the past, standards were set for Total Suspended Particulates (TSP), but those have now been mostly superseded by more specific ones such as PM2.5, PM10, inhalable particulates, respirable particulates, etc.

Health: See the above general discussion for dust and the following discussions for PM10 and PM2.5.

Control: Control measures for dust will directly reduce PM. In addition, for facilities with significant air emissions, IFC recommends considering the following principal methods for controlling the release of particulate matter:

- identify measures for improving operating and management practices

- consider alternative fuels such as gas instead of coal

- consider fuel-cleaning options such as coal washing, which can reduce ash content by up to 40%.

- consider alternative production processes and technologies, such as fluidized bed combustion, that result in reduced PM emissions.

- select optimal particulate removal devices such as ESPs and baghouses.

Other control measures to consider include:

- use of water suppression for control of loose materials on paved or unpaved road surfaces

- use of dust control methods, such as covers, water suppression, or increased moisture content for open materials storage piles, or controls, including air extraction

Also, see Nij et al (2002) for a comprehensive assessment of the effectiveness of dust control measures used in the construction industry.

PM10 (Coarse Particulates)

Definition: PM10 is generality considered to be fraction of particulate with a diameter of 10 µm or less, e.g., WHO, EPA. This fraction may also be referred to as coarse dust or coarse particulate fraction or inhalable particulate matter. PM10 is visible to the eye and is essentially what we colloquially refer to as dust.

Sources: Sources include crushing or grinding operations, construction sites, mining sites, road dust and similar sources. These particles can be transported over very large distances, e.g., Zhu et al (2011) analyzed PM10 data from 2003 to 2009 in China and concluded that 26% of PM10 in Beijing was composed of sand and dust sources 1000-2000 km away.

Regulations: PM10 is generally used for ambient air quality monitoring to measure exposure to the public, rather than for industrial hygiene purposes. It is often used as one of the air quality parameter to assess and monitor potential impacts on nearby communities resulting from emissions from industrial facilities, construction sites, etc. A standard for PM10 was first introduced by the USEPA in 1987 to replace the TSP standard. EPA’s health-based national air quality standard for PM10 is 50 µg/m3 (annual mean) and 150 µg/m3 (24-hour mean). WHO’s standard is lower: 20 µg/m3 (annual mean) and 150 µg/m3 (24-hour mean). Most countries will have their own regulations for PM10, that are similar to these values. For instance, China has different standards for residential zones, commercial areas and industrial zones. Average annual mean standards for these areas are 40, 100 and 150 µg/m3, respectively; average daily mean standards for these areas are 50, 150 and 250 µg/m3, respectively

Health: The WHO report on the health effects of particulate matter includes a discussion of both PM10 and PM2.5, inhalable particles that are small enough to penetrate the thoracic region of the respiratory system. The health effects of inhalable PM are well documented and due to exposure over both the short term (hours, days) and long term (months, years) and include:

- respiratory and cardiovascular morbidity, such as aggravation of asthma, respiratory symptoms and an increase in hospital admissions

- mortality from cardiovascular and respiratory diseases and from lung cancer

There is good evidence of the effects of short-term exposure to PM10 on respiratory health. But, for mortality and especially as a consequence of long-term exposure, PM2.5 is a stronger risk factor than the coarse part of PM10 (particles in the 2.5–10 µm range).

Control: See the control measures discussed above for dust and PM.

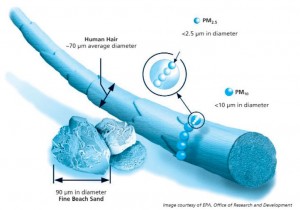

Size Comparison of Human Hair to PM 2.5 and PM10 diameter particles

PM2.5 (Fine Particulates)

Definition: PM2.5 is generality considered to be fraction of particulate with a diameter of 2.5 µ or less, e.g., WHO, EPA. This fraction may also be referred to as the fine dust, fine particulate or respirable particulate matter fraction. PM2.5 is visible to the eye as smoke or smog.

The nanotechnology industry is producing many exciting and mind-blowing new product, but there is a downside. Workers are now starting to facing exposures to nanoparticles, which are defined as particles less than 100 nanometers (0.1 µm). There are potentially serious worker health issues from exposure to nanoparticles and few regulations in place. This is a rapidly evolving issue but one that we will not discuss in this post. If interested, there are many good resources online to explore further – this OSHA fact sheet is a good starting point.

Sources: EPA notes that fine particle pollution can be emitted directly or formed secondarily in the atmosphere. Sulfates are a type of secondary particle formed from sulfur dioxide emissions from power plants and industrial facilities. Nitrates, another a type of fine particle, are formed from emissions of nitrogen oxides from power plants, automobiles, and other combustion sources. Mathys et al (2004) studied sources of workplace PM2.5 in Finland and found that sources included long-range transport of aerosols loaded by sulphur, black smoke from traffic and wood burning, indoor aerosols from cleaning and soil mineral dust from indoor and outdoor sources.

Regulations: Like PM10, PM2.5 is generally used for ambient air quality monitoring to measure exposure to the public, rather than for industrial hygiene purposes. EPA’s health-based national air quality standard for PM2.5 is 12 µg/m3 (annual mean) and 35 µg/m3 (24-hour mean). WHO’s standard is lower: 10 µg/m3 (annual mean) and 25 µg/m3 (24-hour mean). Most countries will have their own regulations for PM2.5. For instance, China has different standards for residential zones, commercial areas and industrial zones. Average annual mean standards for these areas are 40, 100 and 150 µg/m3, respectively; average daily mean standards for these areas are 50, 150 and 250 µg/m3, respectively.

Health: The WHO report on the health effects of particulate matter indicates that long-term exposure to PM2.5 is associated with an increase in the long-term risk of cardiopulmonary mortality. Susceptible groups with pre-existing lung or heart disease, as well as elderly people and children, are particularly vulnerable. For example, exposure to PM affects lung development in children, including reversible deficits in lung function as well as chronically reduced lung growth rate and a deficit in long-term lung function. There is no evidence of a safe level of exposure or a threshold below which no adverse health effects occur. It was noted in the WHO report that the evidence for the hazardous nature of combustion-related PM (from both mobile and stationary sources) is more consistent than that for PM from other sources. The black carbon part of PM2.5, which results from incomplete combustion, is currently seen as responsible for health effects, for instance organics such as PAHs that are known carcinogens and directly toxic to the cells, as well as metals and inorganic salts.

Control: EPA provides a detailed list of both general and industry-specific source control measures, for example:

- review uncontrolled or under-controlled stacks for improvements

- upgrade to high-efficiency collection device to collect fine fraction of PM

- upgrade electrostatic precipitators ESP to improve efficiency on fine fraction of PM

- improve fugitive emissions capture

- various controls for open storage piles, primary crushing operations, and conveying systems

- reduce sulphur in feedstock/fuel

- reduce flaring

PPE should of course be used as appropriate, and as discussed in the preceding sections.

In Part 2 we will close out this post with a discussion of smoke, fumes, aerosols and mists and offer suggestions at to what you can do to identify and evaluate whether you have a serious problem at your site.

Of course, if you have any concerns about dust/particulates or any other air quality issues at your facility and/or need assistance in designing and/or carrying out the assessment, feel free to contact us. We will most certainly be pleased to help.

Thanks for reading. Keep safe. Be healthy. Respect your environment.

I hope that you will bookmark the blog, share it with your colleagues and visit the blog frequently because you find it informative and helpful. I value your feedback and suggestions for future topics.

Please enter your email in the box at the top of the post and subscribe to our blog HSE Asia – our weekly blog will be emailed directly to you.

Next Week’s Blog Topic: Confused About Dust, Particulates and Fumes in the Workplace? Part 2: Smoke, Fumes, Mist and Aerosols

Photo Credits: Mining truck image courtesy of Freerange Stock Archives at www.freerangestock.com

- Is Your Business Compliant with HSE Regulations? Take Our Quiz to Find Out! - September 16, 2024

- Duty of Care: What it Is and What it Means to Companies Operating in the GCC? - January 28, 2024

- Free E-Book:Health, Safety, and Environment Regulatory Review – United Arab Emirates: An Overview of Federal Requirements - July 5, 2023

Dear Randall

Thanks for sharing your knowledge. This was very interesting as the topic is a bit confusing, indeed!

If I understand well the threshold value according to WHO is 25 microgram per cubicmeter for PM2.5.

The generic threshold value (PEL) for respirable dust (not speicifed elswhere) is 5 milligram per cubicmeter for respirable dust (PM4).

0.025 milligram is much lower than 5milligram. I guess this difference is explained by the fact that the dust (not specified elsewehere) is not particularly dangerous whereas environmental dust is related to diesel? Is this correct?

If environmental measurements indicate PM2.5 value above the 25 microgram/m3, I guess they have priority over the occupational health measurements (which might be below 5 milligram/m3)? Respiratory protection would be needed.

Thanks for your help

Chris, thanks for reading and excellent observations. You are pointing out some of the complexities and issues in attempting to manage particulates in the workplace/environment. In particular, as you rightly point out there is an apparent discrepancy/anomaly between the threshold values from WHO for PM2.5 and OSHA for respirable dust. A couple observations, in general environmental guidance/threshold values for any pollutant are bases on protection of the most sensitive population (e.g., infants, pregnant women, elderly, etc.), while OSHA values are bases on a different group of receptors, namely workers. As such, guidance values are almost always more restrictive for environmental (off-site) scenarios compares to occupational health (on-site) scenarios. Also, there are differences between regulatory authorities in how they derive their guidance/regulatory levels, particularly when attempting to derive values for a generic parameter like PM or dust. Finally, the WHO and OSHA are also based on different time-weighting (24-hr vs 8-hr TWA exposures, respectively). All of these affect the final derived values and indeed make it challenging for the HSE professional to figure out which value(s) to select for their particular facility. I trust this helps.

.

Randall,

Thank you for clearing all this jumbaloo (I am not even sure if this is a word) and breaking it down into snackable, easily understood bits. I would appreciate a minor assistance from you if it’s no bother. I am a bit confused, if PM10 and PM2.5 are mostly used for public exposure and not industrial hygiene, then what are the parameters considered in industrial hygiene? Are they any lower or higher than those of public exposure? Kind Regards.

Your most welcome and I am glad you found it useful.

The specific size for PM from a regulatory perspective is whatever the local jurisdiction states in their regulations, the trend is moving from PM10 to PM2.5 or smaller. So, depends on your location and industry. Remember these are simply aggregates of all particles below a certain size and there can be a lot of difference in how they affect humans (or other organisms) based on many factors such as the chemicals constituents, shape, etc.